Investment casting, also known as lost wax casting, is a highly versatile process that has revolutionized the manufacturing industry. With the ability to create complex components using a wide range of alloys, this technique has become a vital tool for various sectors, including automotive, aerospace, and energy. In this blog post, we will delve deeper into the world of investment casting, exploring its benefits, applications, and the crucial role of investment casting wax.

Investment casting is an ancient manufacturing method that dates back thousands of years. Utilizing the lost wax casting technique, this process involves creating a wax model, or pattern, which is subsequently coated with a ceramic material. Once the ceramic shell is dried and cured, it is heated, causing the wax to melt and flow out of the shell, leaving behind a hollow mold. Molten metal is then poured into the mold, filling the intricate cavities of the pattern. After the metal solidifies, the ceramic shell is broken or dissolved, revealing the final cast component.

One of the primary advantages of investment casting is its ability to produce highly intricate and complex components, often with minimal post-processing required. This makes it an ideal choice for the manufacturing of components with intricate geometries, fine details, and thin walls. Investment casting allows for the production of parts with excellent dimensional accuracy, tight tolerances, and smooth surface finishes, eliminating the need for extensive machining operations.

The wide range of alloys that can be utilized in investment casting is another major advantage. Almost any alloy can be used, including ferrous metals like stainless steel, carbon steel, and alloy steels, as well as non-ferrous metals such as aluminum, brass, bronze, and titanium. This versatility enables manufacturers to choose materials that best suit their specific application requirements, ensuring optimal performance and durability.

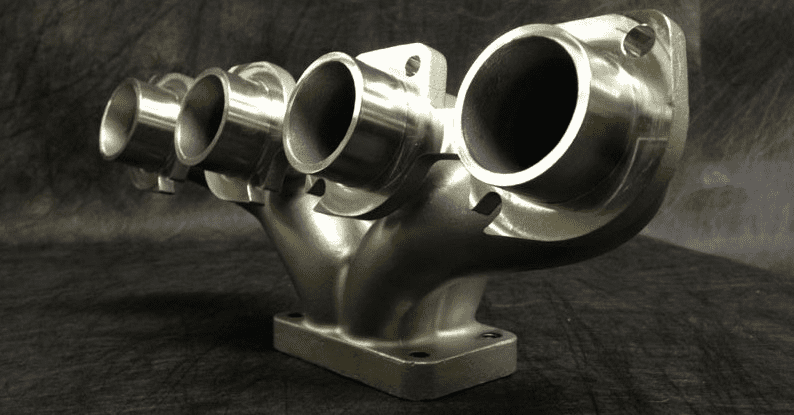

In the automotive industry, investment casting plays a crucial role in the production of engine and transmission components, suspension parts, and turbocharger impellers. The ability to create complex shapes and thin-walled structures enables the automotive sector to reduce weight and improve fuel efficiency without compromising performance or safety.

Similarly, in the aerospace industry, investment casting is widely employed to manufacture turbine blades, vanes, and other critical components used in jet engines. The intricate and intricate cooling passages in these parts can be accurately reproduced through investment casting, ensuring efficient engine operation and enhanced performance.

Investment casting also finds significant applications in the energy sector, where it is utilized for the production of turbine parts, pump components, and valves. The ability to create complex structures and components with high precision and repeatability makes investment casting an ideal choice for these demanding applications.

Now, let's focus on the indispensable role of investment casting wax in the overall process. Investment casting wax is a specialized wax formulation that is utilized to create the wax patterns or models. This wax is carefully selected based on its properties, allowing for easy shaping, low viscosity for intricate details, and high melting point to withstand the high temperatures of the ceramic shell.

Investment casting wax plays a critical role in achieving the desired dimensional accuracy and surface finish of the final cast component. The wax patterns are typically injected into metal dies using injection molding techniques, ensuring the precise replication of intricate features. This high precision enables manufacturers to meet tight tolerances and produce components with minimal post-processing, saving time and cost.

Apart from its role in creating patterns, investment casting wax also enables the efficient and cost-effective production of large quantities of identical components. The wax patterns can be replicated easily using molds or dies, allowing for mass production while maintaining consistency and quality.

In conclusion, investment casting, or lost wax casting, is a highly versatile process that has revolutionized the manufacturing industry. With the ability to create complex components using a wide range of alloys, it has become a vital tool for various sectors. The use of investment casting wax is crucial in achieving the desired precision, dimensional accuracy, and surface finish of the final cast components. As the demand for intricate and high-quality components continues to rise, investment casting continues to play a pivotal role in meeting these requirements efficiently and effectively.